Bringing Industries to Industry 4.0 and Beyond

This is an accordion element with a series of buttons that open and close related content panels.

Robust fault detection of manufacturing machines enabling widespread deployment

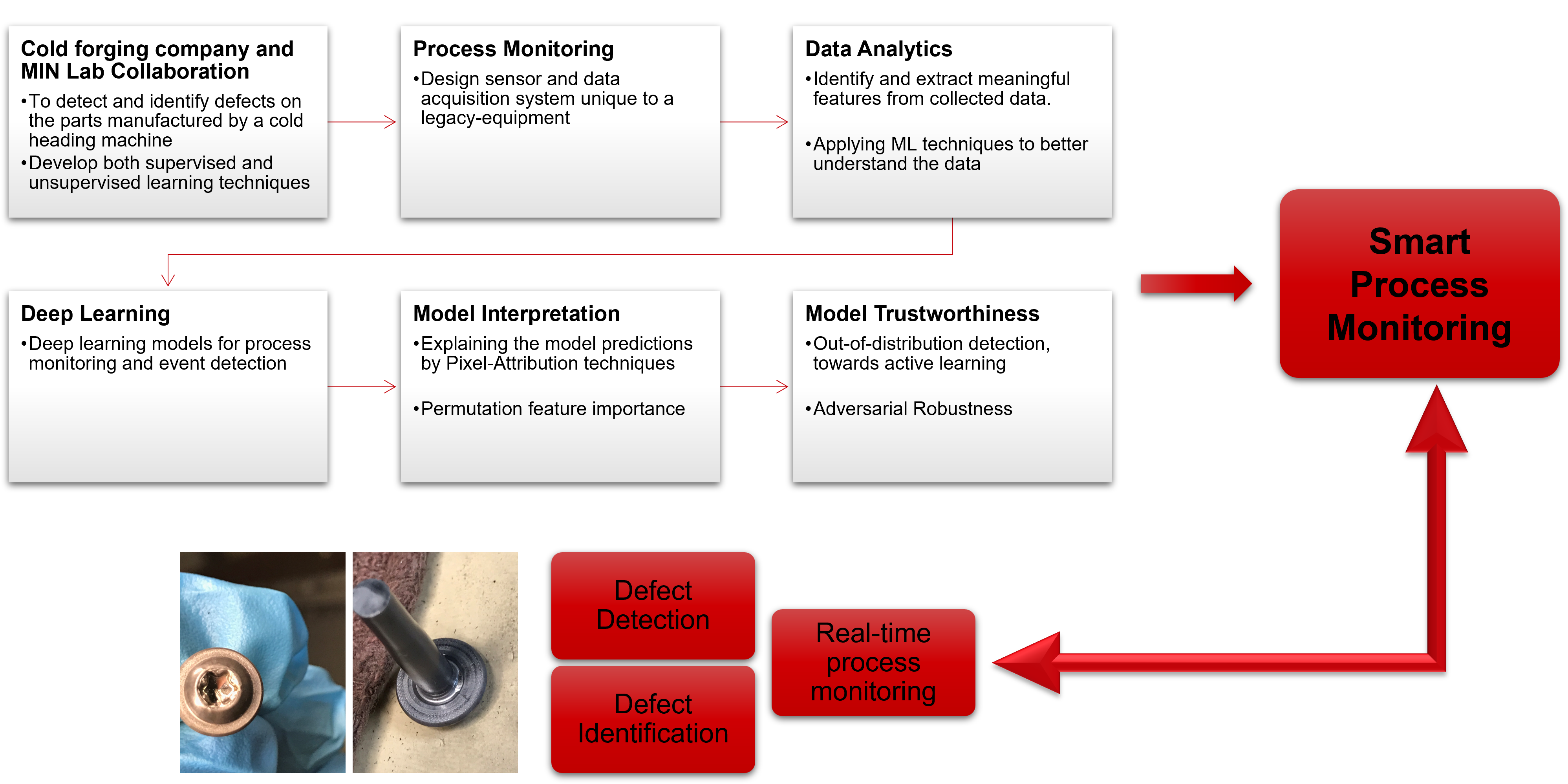

Overarching Research Goals

Immediate

- Defect detection and identification

- Anomaly detection

- Process-physics integrated learning

Midterm

- Robust model development, robust training

- Model explainability and model interpretability

- Out-of-distribution (OOD) detection

Long-term

- Life-long learning (LML)

- Learning without forgetting (LwF)

- OOD integrated learning

Research Team: Vignesh Selvaraj

Through this work we aim to develop systematic approaches to build robust and trustworthy AI for industrial applications. Our work focuses not only building reliable physics informed models for industrial applications and machines, but also ensures their reliability in field. Through our work, we aim to facilitate industries’ transition to industry 4.0 by enabling widespread deployment of the developed models.

Through the course of this research work we have been able to do the following,

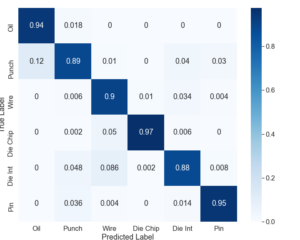

- Detect and identify defects for a manufacturing machine

- Development reliable model architectures

- Combining process-physics at the model development stage

- Detect anomalies with less training data and less-supervision

- Enable cost-effective model development process for manufacturing machines

- Enable life-long learning for supervised models

- Knowledge transfer between machines for widespread deployment and model augmentation (increase in learning tasks)

- Strategies to deploy a single model across multitude of similar machines

- Learning without forgetting

- Explaining the model’s operation to build trust

- OOD detection

Industrial Case Study

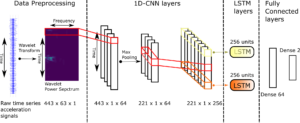

Model Architecture exploiting both spatial and temporal resolution Defect Identification

Intelligent Assembly Monitoring using Deep Learning

Overarching Research Goals

Immediate

- Human-centric assembly monitoring system

- Assembly step time and cycle time determination using vision cameras

- Assembly operation’s anomaly detection

Midterm

- Designing novel deep learning architectures

- Identifying non-value-added activities without explicit training

- Improving the current inference architecture

Long-term

- Integrating user feedback for model updates

- Knowledge transfer of NVA activities

- Development of a full-fledged assembly guidance system for AI in factories

Why do we do it?

In industries, up to 40% of the cost and 70% of the production time falls under assembly operations, either in intermediate assembly operations or in final finished product assemblies. Hence, the end-product quality and the lead time of a product are hugely impacted by the quality of the assembly operations

Current Challenges:

- Continuous monitoring of human-centric assembly operations can be expensive

- The current approach of using hand-worn sensors can cause safety and privacy concerns

- When using hand-worn sensors, the operators have the authority to ensure that the sensors are always operational

- Any hand-worn or body-worn sensors can be a hassle to the assembly operators

Hence, we propose a non-contact approach to monitoring the assembly operations using sensors like vision, etc.

Research Progress

We have developed an assembly monitoring system that can ac the following:

- Accurately determine the step and cycle time in real time using vision cameras

- Identify anomalies like sequence break and missed steps when happens

- Guide the assembly operators in real time by identifying the parts and components of the subsequent step

- Can detect non-value-added activities reliably without explicit model training i.e., information on the assembly steps is all that is required for the system to function effectively

- An application was developed to showcase the system making inference in real-time. See below,

Energy Monitoring

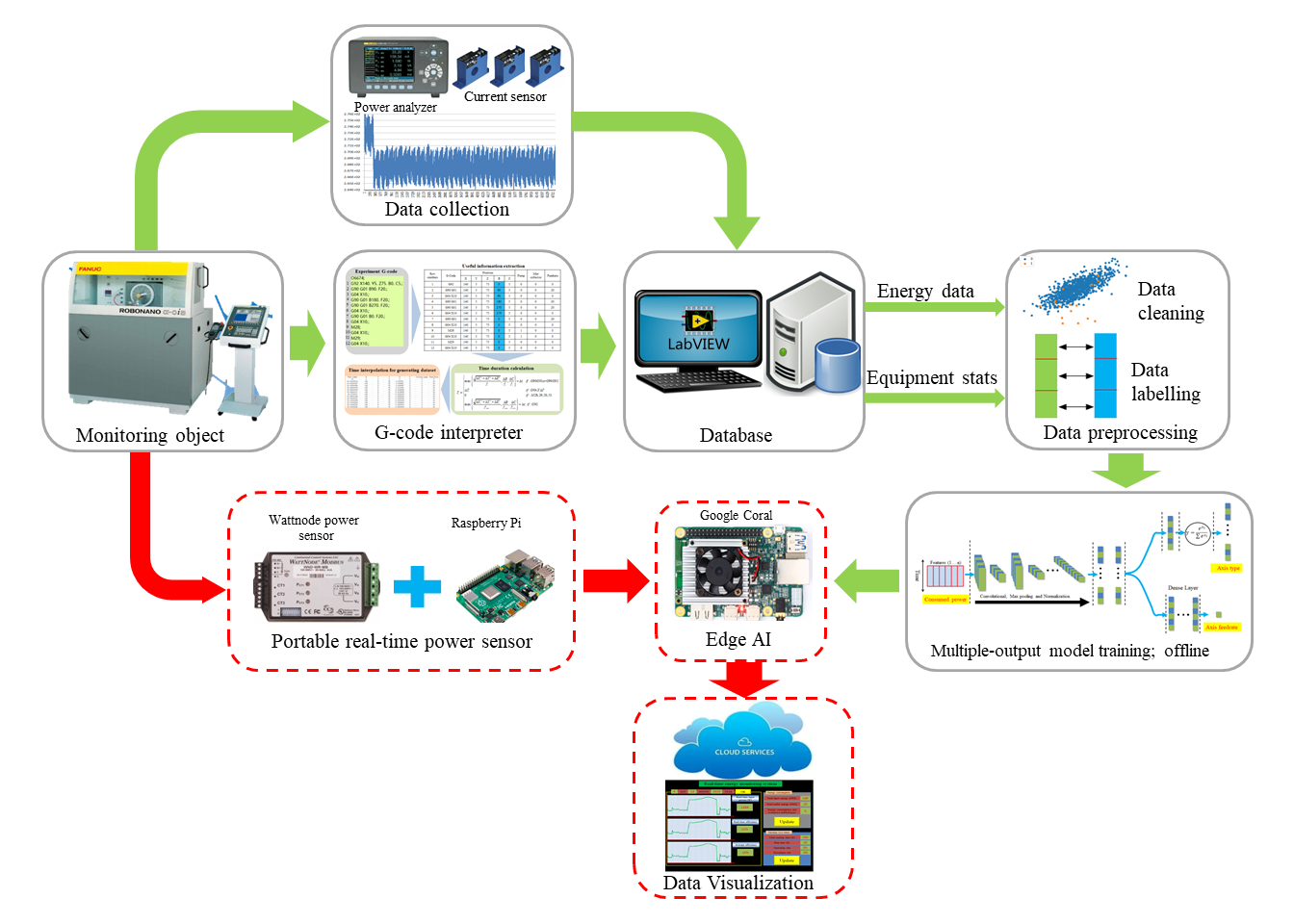

Overarching Research Goals

Immediate

- Equipment status identification from energy consumption

- Feed rate prediction from energy consumption

- G-code interpretation, in relevance to energy consumption

Midterm

- G-code interpretation and energy prediction

- Equipment anomaly detection

Long-term

- Real-time energy consumption monitoring

- Real-time equipment status identification and anomaly detection

- Equipment operation optimization constrained by energy consumption

Research Team: Vignesh Selvaraj

Manufacturing is responsible for almost 45% of total energy consumption in the US and a similar portion in other countries. Machine energy consumption accounts for a big portion of 45% and thus understanding how machine tools consume energy helps to minimize energy consumption by design optimization of the machine tools, strategic operation control, energy balance on the production line, and energy footprint and control of supply chain. Monitoring and control of horizontal and vertical integration of total manufacturing infra can be achieved by IIoT (Industrial Internet of Thing) with a similar manufacturing paradigm called smart manufacturing, digital manufacturing, and industry 4.0.

Through the course of this research work, we have been able to do the following,

- Identify equipment operating status just from the energy data

- Components active at any point in time

- Axis in motion at any point in time

- Develop an application that can interpret G-code and generate working status matrix and model training data

- The application is open source

- The application is deployed in AWS and will soon have the ability to predict the energy from G-code

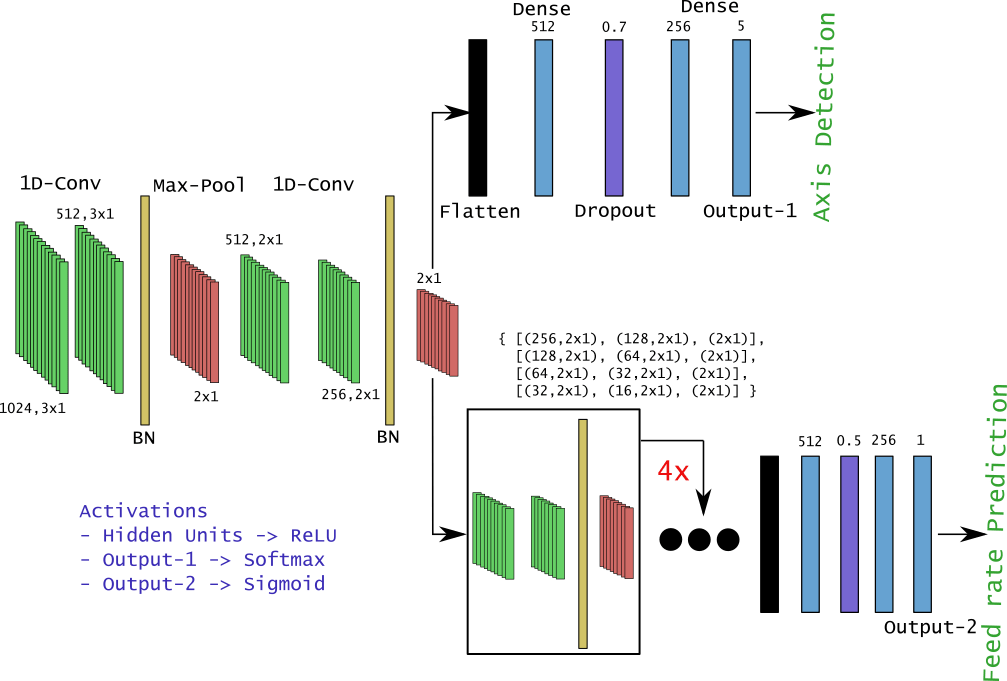

- Develop a multi-task model that can predict feed rate and simultaneously predict the axis in motion

- The model can be expanded to carry out more related tasks

- The model has an accuracy of ~95%

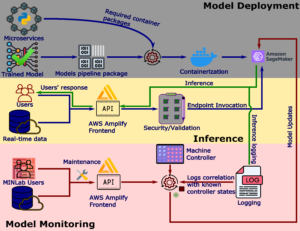

- Deploy a real-time monitoring system for a CNC machine at AWS

- Real-time monitoring of energy

- It will soon be integrated with MTConnect

Framework for model development and deployment

- The real-time energy dashboard can be seen here

Model augmentation with multi-tasking

- The equipment state and feed rate can be determined from the energy consumption data of the machines

An instance of a fault detection system deployment

- Models hosted using AWS

- The real-time fault detection system can be found here

Digital-gradient Cascade Manufacturing of Core-multi-shell Cathode Materials

Research Team: Dr. Sangjin Maeng, in collaboration with Dr. Youngho Shin @ Argonne National Laboratory

In order to overcome structural and surface instability of Ni-rich cathode materials which causes poor cyclability and thermal stability, cathode materials with a digital-gradient particle structure wrapping Ni-rich high-capacity core with Mn-rich high-stability multi-shells were synthesized successfully by Argonne National Laboratory. Mechanical properties of cathode particles is closely related to battery life and mechanical characterization of synthesized particles are being studied.