MAUM: A NEW INDUSTRIAL CONSORTIUM ADDRESSING REAL-WORLD MANUFACTURING CHALLENGES

MAUM (Manufacturing Advancement through Unprecedented Morphing) officially launched on February 1, 2024. The consortium is dedicated to solving pressing industrial manufacturing problems through direct collaboration between academia and industry.

MAUM operates with three integrated objectives:

- delivering practical solutions to real-world manufacturing challenges,

- providing hands-on training for manufacturing engineers in advanced and smart manufacturing technologies, and

- building a strong workforce pipeline for the future of manufacturing.

By combining applied research with industry engagement, MAUM equips professionals with actionable knowledge and prepares students to understand and address authentic industrial problems. Through this model, the consortium cultivates technically strong, industry-ready leaders capable of navigating and advancing the rapidly evolving manufacturing landscape.

News

International Conference on PRecision Engineering and Sustainable Manufacturing

July 7 – 12, 2024, Paradise Hotel, Busan, Korea

Call for Papers on Research Trends in Ultra-Precision Machining for High-Quality Parts and the Related Measurement Technologies

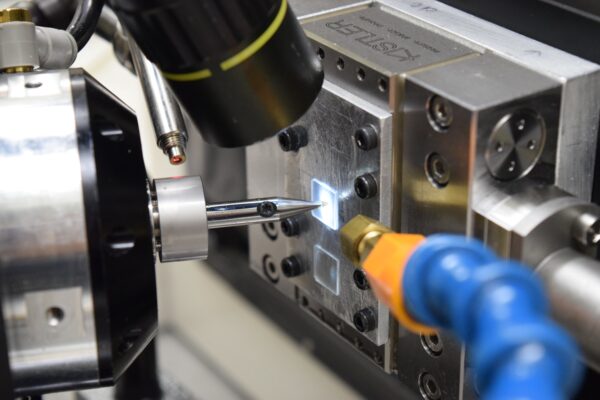

The demand for 4K and 8K resolution imaging devices enriching our lives is increasing these days. In the smartphone market, more and more small and highly accurate aspherical lenses will be required in the future. In the field of automobiles, functional optical devices like communication lighting applications are currently attracting attention. In order to provide these cutting-edge optical devices, conventional machining with conventional machine tools is not applicable to the manufacturing process because sharper diamond tools and higher positioning accuracy are essential. Therefore, it is necessary to develop Ultra-Precision Machining Technologies and Measurement Technologies that enable the production of high-quality mold and die or large-aperture lenses with complex shapes.

Ultra-Precision Machining is the frontier of research in Production Engineering and needs to be further developed from both the academic and industrial viewpoints. Modeling based on process analysis in Ultra-Precision Machining, especially for high-quality optical parts, has not been sufficiently performed and systematized. Measurement Technologies also play an essential role in the development of Ultra-Precision Machining such as tool tip shape measurement and contact detection of tool and material. As well as these, Measurement Technologies for machined materials with measurement of high aspect ratio structure are needed to address.

This Research Topic contributes to the understanding of the interaction between tool and material, to the development of models in Ultra-Precision Machining of advanced materials, and to the creation of advanced machining technologies to provide higher quality parts.

This Research Topic covers the following areas of research:

• Ultra-Precision Machining (UPM) process of hard-and-brittle materials and advanced materials

• Advanced cutting/grinding tool technology for UPM

• Unconventional machining processes for UPM

• Vibration-assisted UPM including fast tool servo

• Precision machine technologies and precision machine elements

• Process monitoring and process control for UPM, Digital Twin for UPM, IoT based technology for UPM

• Tool path generation

• Contact/non-contact measurement technology

• On-machine/in-situ/in-process measurement

• Error assessment and compensation

• Surface integrity and related technologies

We are interested in contributions that cover academic research and industrial technology.

Keywords: Ultra-Precision Cutting, Ultra-Precision Grinding, Vibration-Assisted Machining, Optical Measurement Technology, Contact Measurement Technology, Hard-and-Brittle Materials, Non-Metal Materials, Surface Integrity, Cutting Tool Technology, Grinding Tool Technology

Important Note: All contributions to this Research Topic must be within the scope of the section and journal to which they are submitted, as defined in their mission statements. Frontiers reserves the right to guide an out-of-scope manuscript to a more suitable section or journal at any stage of peer review.

Recent Journal Publications

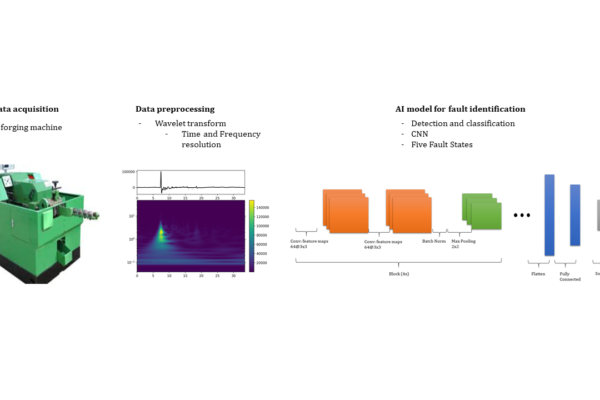

Intelligent G-code-based power prediction of ultra-precision CNC machine tools through 1DCNN-LSTM-Attention model

As the most promising and advanced technology, ultra-precision machining (UPM) has dramatically increased its production volume for wide-range applications in various high-tech fields such as chips, optics, microcircuits, biotechnology, etc. The concomitantly negative environmental impact …

AI-assisted Monitoring of Human-centered Assembly: A Comprehensive Review

Detection and localization of activities in a human-centric manufacturing assembly operation will help improve manufacturing process optimization. Through the human-in-loop approach, the step time and cycle time of the manufacturing assemblies can be continuously monitored …

Intelligent assembly operations monitoring with the ability to detect non-value-added activities as out-of-distribution (ood) instances.

Recognition and localization of actions in manufacturing assembly operations improves productivity and product quality by identifying bottlenecks and assembly errors. In our previous work, we developed an approach that can recognize and localize the assembly standard operating procedures (SOP) …

Real-time action localization of manual assembly operations using deep learning and augmented inference state machines

The real-time monitoring of assembly operations in manufacturing industries can be used for manufacturing process optimization, which is crucial to manufacturers. It helps to improve productivity by automatically identifying the bottleneck and enhancing product quality by detecting …

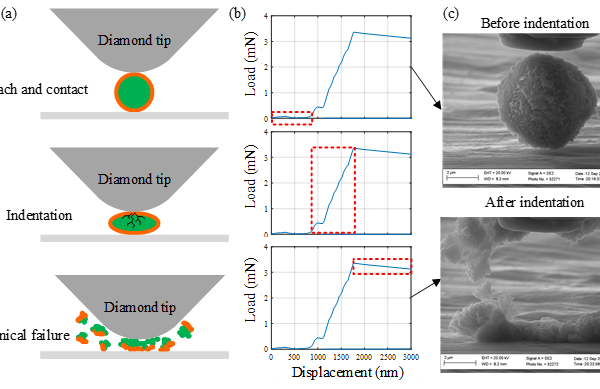

Studying Crack Generation Mechanism in Single‐Crystal Sapphire During Ultra‐precision Machining by MD Simulation‐Based Slip/ Fracture Activation Model

Single-crystal sapphire is used in various fields of industry due to its superior mechanical, optical, and chemical properties, but fabricating sapphire is challenging because of its high hardness and brittleness. Ultra-precision machining (UPM) has been …